The Bolt and the Bolt Load

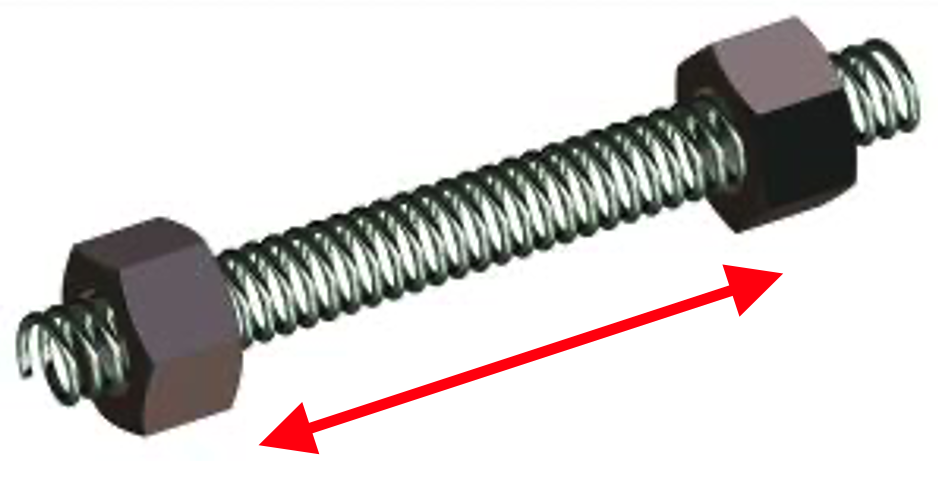

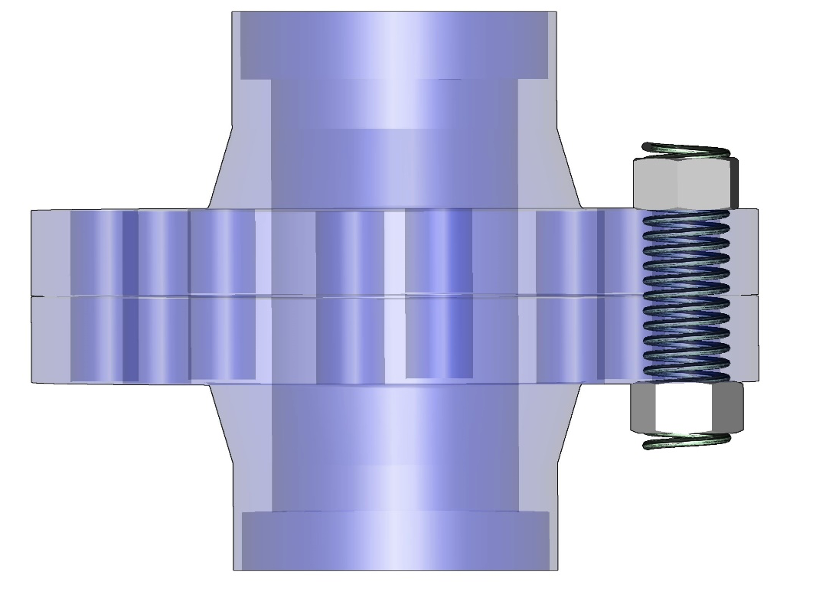

The Clamping Force is achieved by tightening the bolt. The tightening stretches the bolt like a spring, which in turn wishes to contract providing Bolt Load.

Like a spring

All bolt tightening procedures result in stretching the bolts. Torque tightening utilises the thread form, by turning the nut in a clockwise direction to induce the physical stretching of the bolt against the flange face,

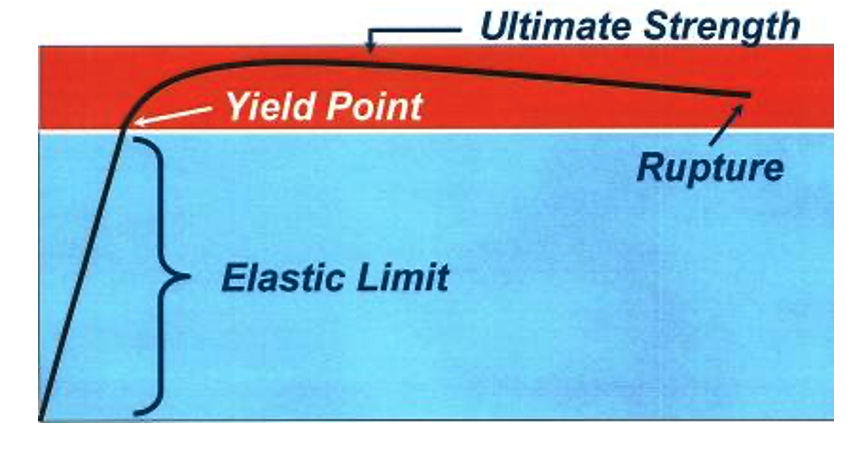

Bolt extension must remain within the elastic limit for its particular material.

Too much extension of the bolt beyond its elastic limit will take the bolt into yield and can eventually break.

Load Applied

Extension of Bolt / Stud

When a bolt is stretched beyond its Elastic Limit into Yield, it loses its spring effect and cannot return to its original length. Without its spring effect, a bolt cannot produce an effective Clamping Force.

The load retained in the bolt(s) (Residual Bolt Load) must be correctly maintained during the flanges scheduled working life, maintaining a leak free system.

A sealing application is where the load retaining bolts require an applied load, to provide the clamping force. This not only maintains the flange integrity, but provides sufficient compression on the gasket to achieve a seal.

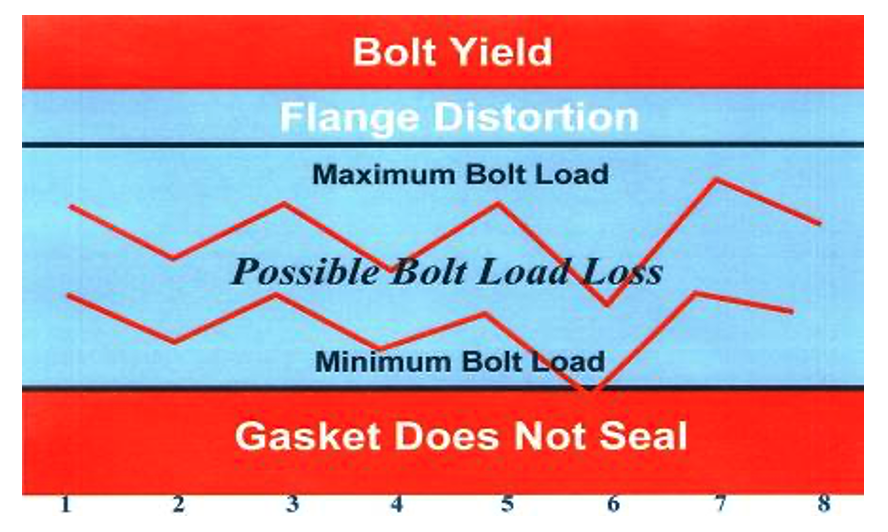

For the Bolt Load, to be effective, we must always remain between two limits: -

The minimum load to compress and seal the gasket. The maximum load to avoid distorting the flange or yielding the bolt.

There is a minimum and maximum range for the bolt loadings that are applied. This will differ depending on the application.

The bolt load application takes into account the following:-

- External forces that might be preventing the flanges meeting.

- The material strength of the flange(s) and bolts.

- The gasket(s) compression tightness factor.

- Known forces like internal pressure that will attempt to force the

- flanges apart (Test and Operating).

- Bolt Load loss that may occur during the process.

- High temperature stress relaxation.

The bolt load line shown as the uppermost portion of the bolt load range shows the applied loads induced into the bolts. The bolt load line shown at the bottom section of the load range shows the potential load that we could see.

Bolt Load loss can be either:-

Specific information is required to carry out accurate bolting calculations. I.e. thread deflection, bolt relaxation etc.

Calculations carried out do not account for flange misalignment or pipeline tension usually due to bad assembly procedures or poor manufacturing processes.